In today’s rapidly evolving technological landscape, electronics play an indispensable role in every facet of our lives. From the smartphones that keep us connected to the complex systems powering industries, electronics are the foundation of the digital age. At the heart of this phenomenon lies the intricate world of electronics manufacturing and Printed Circuit Board (PCB) assembly, the unsung heroes responsible for bringing our devices to life.

The Evolution of Electronics Manufacturing

The journey of electronics manufacturing is a testament to human innovation. It all began with vacuum tubes and discrete components in the mid-20th century. These bulky, inefficient components paved the way for transistors, integrated circuits (ICs), and microprocessors, enabling the miniaturization and enhanced performance we now take for granted. Key milestones, such as the invention of the integrated circuit by Jack Kilby and Robert Noyce’s development of the microchip, propelled the industry into a new era.

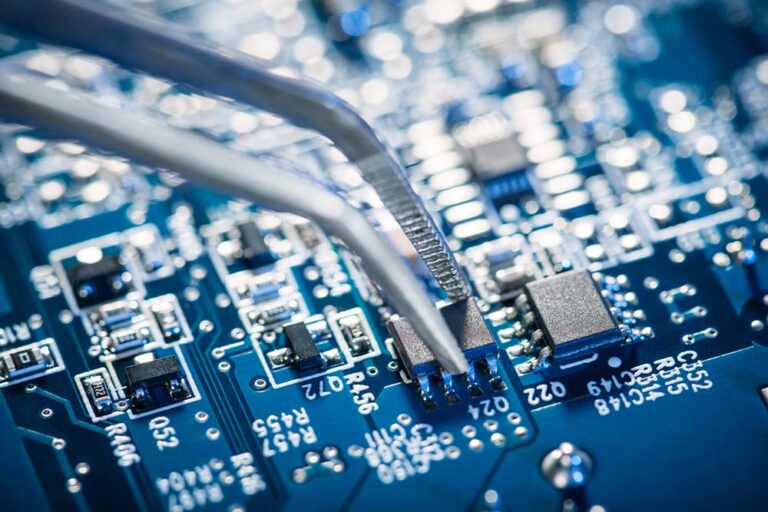

Understanding PCB Assembly

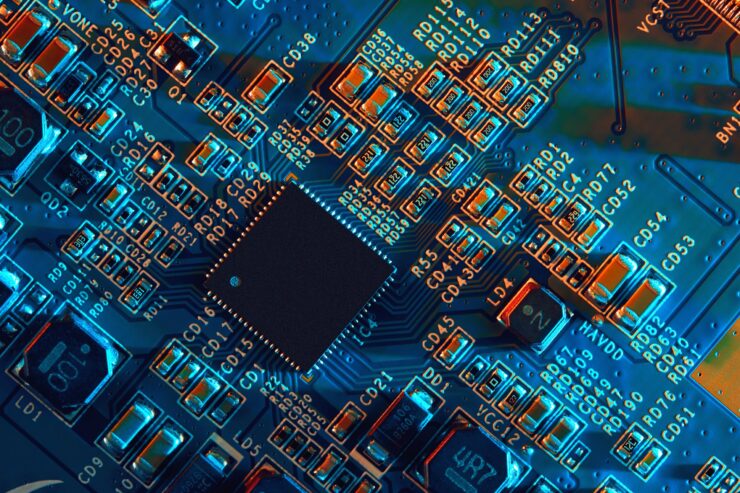

Central to electronics manufacturing is the PCB, a flat board that serves as a foundation for connecting and supporting electronic components. PCB assembly involves the intricate process of attaching components to the board’s surface, creating an interconnected network that defines a device’s functionality. This symbiotic relationship between the PCB and its components is the bedrock of modern electronics. If you want to see how professionals do it, please visit Vinatronic and experience it firsthand.

PCB Design and Layout

The design and layout of a PCB is a delicate dance of art and science, shaping the very essence of electronic innovation. Engineers meticulously plan component placement to optimize signal integrity, minimize interference, and ensure efficient heat dissipation, giving birth to devices that surpass expectations. Factors like trace routing, layer stacking, power distribution, and impedance control must be carefully considered to achieve optimal performance. Today’s sophisticated design software empowers engineers to visualize and optimize their designs with unprecedented accuracy, making the process more efficient than ever before.

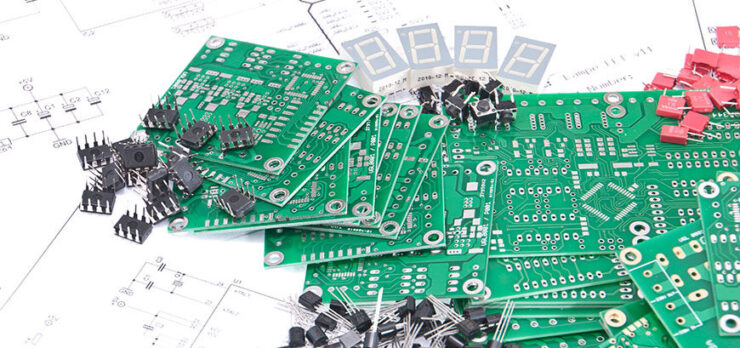

Component Sourcing and Procurement

The journey of a PCB begins with a symphony of coordination in sourcing electronic components. Engineers, acting as orchestrators, collaborate closely with suppliers to procure a diverse array of components ranging from resistors to microcontrollers. Here, reliability is the unshakable foundation; the importance of trustworthy suppliers cannot be overstated. The specter of counterfeit components looms, capable of inducing catastrophic failures. Thus, rigorous supplier vetting processes and supply chain transparency stand as unwavering safeguards against these lurking risks.

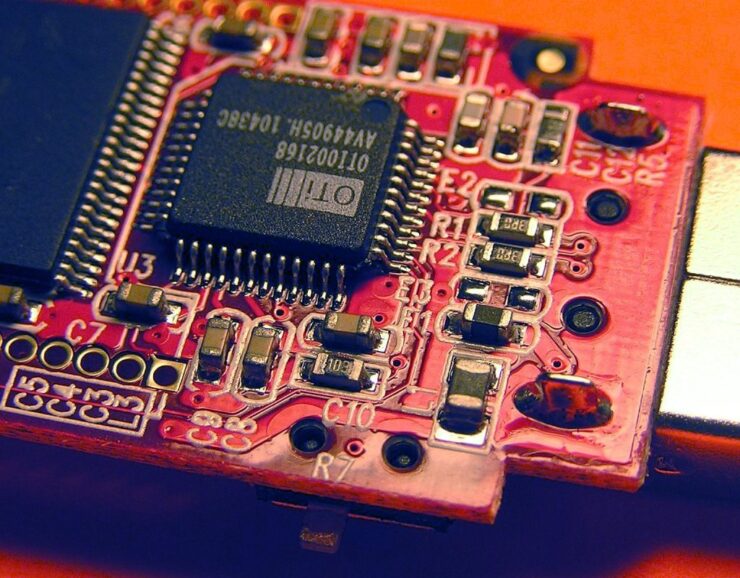

Surface Mount Technology (SMT) vs. Through-Hole Technology

In the grand theater of electronics manufacturing, two primary assembly methods take center stage: Surface Mount Technology (SMT) and Through-Hole Technology. SMT emerges as the avant-garde technique, enabling components to take their place directly on the PCB’s surface, ushering in an era of smaller, sleeker, and lighter devices. On the other hand, Through-Hole Technology preserves a classic elegance by involving the insertion of leads into holes and soldering on the flip side. This juxtaposition of modern innovation and timeless tradition shapes the manufacturing landscape, offering a spectrum of choices to designers and engineers.

While SMT offers advantages in miniaturization and cost-efficiency, Through-Hole remains relevant for certain applications that demand robustness.

The PCB Assembly Process

The PCB assembly process is a symphony of precise steps. It starts with applying solder paste to the board’s pads, followed by automated or manual component placement. The board then enters a reflow oven, where the solder paste melts, creating solid connections. After cooling, inspection ensures quality, and any defects are rectified. This meticulous process guarantees the device’s reliability and functionality.

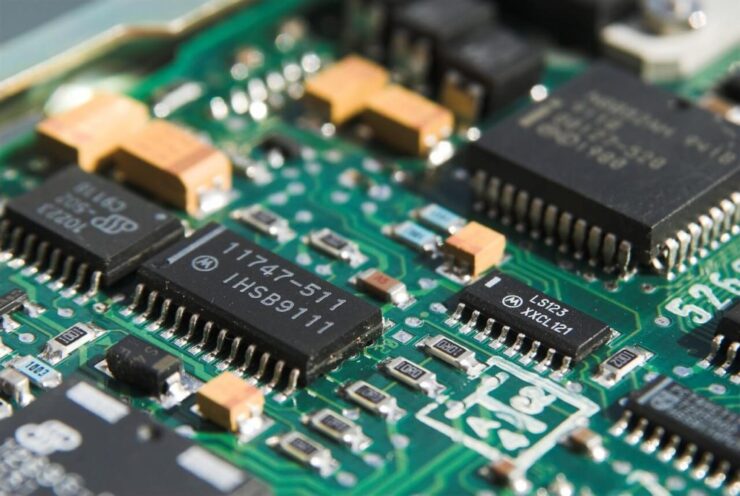

Advanced Manufacturing Techniques

As technology progresses, so do manufacturing techniques. Automated assembly, powered by robotics and machine learning, has revolutionized the industry. Robots now perform intricate tasks with unparalleled precision, increasing efficiency and consistency. Machine learning algorithms assist in quality control, identifying defects that human inspectors might miss. These advancements mark a new era of high-tech manufacturing.

Challenges in Electronics Manufacturing

With every stride forward comes new challenges. Miniaturization presents the puzzle of fitting complex components into ever-shrinking spaces. Thermal management is crucial to prevent overheating in compact devices. Environmental concerns drive the need for sustainable practices, as electronic waste grows. Addressing these challenges requires collaborative efforts from engineers, manufacturers, and policymakers.

Quality Control and Testing

Quality control is the backbone of electronics manufacturing. Rigorous testing ensures that devices meet stringent performance standards and endure real-world conditions. Through automated optical inspection (AOI) and X-ray inspection, defects that could potentially compromise functionality are meticulously identified. Comprehensive environmental and reliability testing goes beyond the initial phases, offering a thorough validation of a device’s long-term performance. This process not only ensures functionality but also instills unwavering confidence in consumers regarding the reliability of their electronic companions.

Industry Trends and Future Prospects

The electronics manufacturing landscape is in a constant state of evolution, spurred by dynamic trends such as the Internet of Things (IoT) and wearables. As the IoT continues to weave a web of connectivity, the demand for smaller, energy-efficient components soars, driven by the need for seamless integration. Meanwhile, wearables are pushing boundaries by seamlessly blending technology into our daily routines, necessitating solutions that are both adaptable and space-efficient. The prominence of sustainable practices is surging as environmental awareness takes root, hinting at an industry future focused on deeper miniaturization, heightened energy efficiency, and a profound commitment to environmental stewardship.

Enabling the Digital Revolution

Electronics manufacturing and PCB assembly are the unsung heroes shaping the digital revolution. From the historical evolution of manufacturing techniques to the intricacies of PCB design and layout, this industry’s journey is one of innovation, challenges, and triumphs. Quality control, advanced manufacturing techniques, and the embrace of industry trends propel us towards a future where electronics seamlessly integrate with our lives, making the impossible possible.

Summary

As we navigate challenges and embrace opportunities, let’s remember that the devices we hold, the systems we rely on, and the future we envision are all indebted to the men and women who tirelessly work behind the scenes to build the digital world. The evolution of electronics manufacturing and PCB assembly continues to be a remarkable testament to human ingenuity, pushing the boundaries of what’s possible in the realm of technology.